Stacks+Joules visits RAB Lighting HQ

Stacks+Joules UA Maker cohort on the manufacturing floor at RAB Lighting in Northvale, NJ.

Northvale, NJ., May 1st, 2019 — Stacks+Joules UA Maker cohort went to the source to deepen their understanding of the lighting controls industry by visiting the RAB Lighting headquarters and manufacturing facility. RAB is one of the leading independent Building Automation platforms and manufacturers of LED smart lighting. The class got an end-to-end view of a high tech lighting control business showcasing the professional roles ranging from training, sales, support, manufacturing, shipping, and R&D.

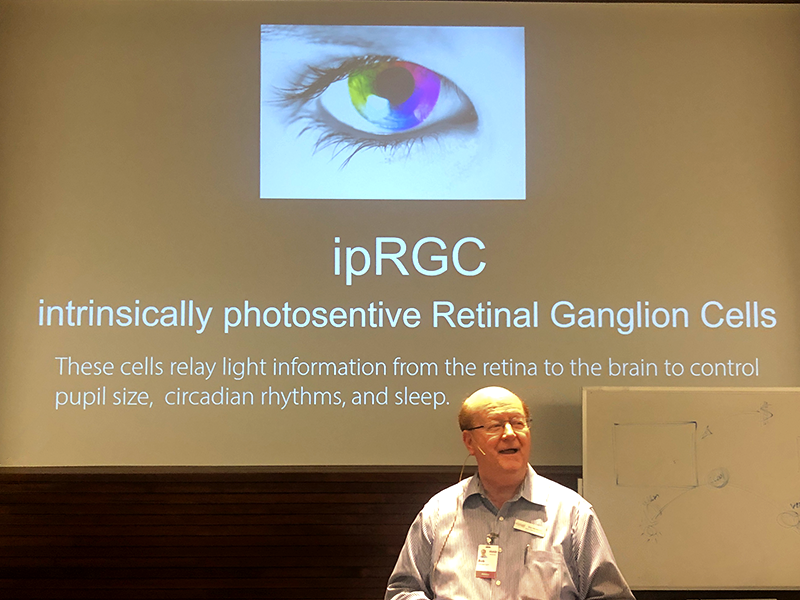

Bob Henderson Director of Training presenting executive level insights to the students.

The entire experience was carefully planned for maximum work-based learning, led by RAB’s Director of Training, Bob Henderson. Our young professionals left high school at the door as they were welcomed into the Executive Training amphitheater. Bob set his expectations at the executive level by sharing the same company overview that lighting industry leaders get when they come to RAB for training. Eyes were wide and questions were flying as our cohort learned of the blistering rate of innovation at RAB. RAB sells over 150,000 SKU’s and introduces new products every two weeks. They didn’t have to be told to bring their best if they wanted to keep up. And we didn’t have to ask!

Ravi Parikh presents to an eager audience of Stacks+Joules students.

Ravi Parikh, Business Development Manager, focused on the importance of ease of use as a selling point. Ravi’s presentation made it clear that making it easy for the customer is at the core of RAB’s culture. The hours they spend mentoring our students are right in line with their commitment to customer service.

Davis Rothenburg’s marketing presentation echoed Stacks+Joules’ emphasis on professional soft skills and the importance of building trust and integrity. The students’ questions and comments connected their classroom learning directly to RAB’s workplace.

Lisa Lowe-Casado explains call center analytics and how they help them deliver the best customer service.

The same deep level of commitment to service was demonstrated at each stage of our tour by every one of the many RAB professionals who shared their expertise with our group. Lisa Lowe-Casado, Director of Customer Service, brought us right in amidst the buzz and hustle of their service center. She showed us the time-to-response analytics that they use to stay on top of customer inquiries. It was music to our ears to hear Lisa’s refrain of “We seek Excellence, not perfection.”. It matches right up with the Stacks+Joules focus on lifelong learning.

Over in the manufacturing area Bruce Azlin, Manufacturing Engineer, picked up where Lisa left off, detailing the careful organization of the workspaces and highlighting the iterative design process that they use to continuously improve. We could clearly see all the work and iterative innovation that had been done to bring their time-to-ship from 16 days down to 3 days. Bruce helped the students see the creativity and problem solving that goes into the manufacturing process design. In an unexpected twist, students turned their curiosity to the automated conveyor system that whirred away in the background. Bruce was impressed with their impromptu analysis of the system of sensors and motors and the control strategies that are programmed into its function.

The final stop was in the product design and testing facilities. Our young professionals were amazed and excited by the level of technology that RAB’s engineers get to “play” with. A large green orb the size of an elevator let the product team test the reflective properties of each of the light bulbs to get a true value of its lumen output. Also, the Goniophotometer* was especially impressive as it’s windmill sized mirrors spun around a light source to test the directional light output. (* a device used for measurement of the light emitted from an object at different angles)

At the end of the day, Bob commented on the student’s enthusiasm and command of the technical aspects of lighting controls. “Who knows! I might be running training on products that you all have created!”. With these students poised to become the next wave of building automation specialists — you should count on it, Bob!